Concrete Grinding Tooling

Why Choose Us

High-quality products

The company is committed to producing high-quality products that meet customer's standards. The company uses advanced technology and equipment to ensure consistency in the quality of its products.

Diverse range of products

The company offers a wide range of grinding tools such as diamond tools, resin tools, ceramic tools, and metal bond tools, among others, to meet the needs of its customers.

Competitive pricing

The companyprovides customers with competitive pricing on its products without compromising their quality.

Excellent customer service

The company has a team of dedicated customer service staff who are always ready to assist customers with their needs and concerns.

What is Concrete Grinding Tooling

Concrete Grinding Tooling refers to the abrasive tools and equipment used for grinding and polishing concrete surfaces. These tools include diamond grinding discs, metal-bonded grinding discs, polishing pads, and hand-held grinders. They are designed to remove surface imperfections, level uneven concrete slabs, and create a smooth and polished finish. Concrete Grinding Tooling is essential for concrete flooring and restoration projects to ensure a durable and aesthetically appealing surface.

Versatile: Concrete Grinding Tooling is versatile and can be used for a range of applications, including surface preparation, concrete leveling, and polishing. This makes it an essential tool for many contractors, as it can be utilized for a variety of projects.

Safe and Environmentally Friendly: Compared to other methods, such as sandblasting, Concrete Grinding Tooling is a safer and more environmentally friendly option. It doesn't produce harmful dust particles or release toxic chemicals into the environment, making it a more sustainable solution for concrete surface preparation.

Improved Efficiency

Concrete Grinding Tooling can greatly improve the efficiency of the grinding process. With the right tooling, you can remove more material in less time, resulting in faster job completion and increased productivity.

Better Surface Finish

Grinding tooling can help you achieve a better surface finish on concrete surfaces. By removing any imperfections or rough spots, you can achieve a smoother finish that is more visually appealing and more functional for various applications.

Cost-Effective

Investing in Concrete Grinding Tooling can be a cost-effective solution for maintaining or refurbishing concrete floors. While the initial cost can be higher than other methods, such as sandblasting or acid etching, the long-term benefits can outweigh the cost.

Concrete Grinding Tooling is used for shaping concrete surfaces, removing coatings and adhesives, preparing surfaces for polishing, leveling surfaces, and removing bumps and irregularities. The tooling can be used on floors, walls, countertops, and other concrete surfaces. It is commonly used in commercial and industrial settings for concrete preparation and surface repair prior to installing new flooring, coatings, or other finishes. Additionally, Concrete Grinding Tooling can be used for decorative purposes, allowing for the creation of intricate designs and patterns in concrete.

Types of Concrete Grinding Tooling

Diamond Grinding Segments: These are the most commonly used tooling for concrete grinding. They are made of diamonds embedded in a metal or resin bond and are available in various shapes, sizes, and grits.

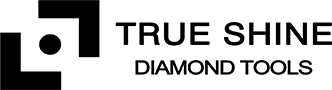

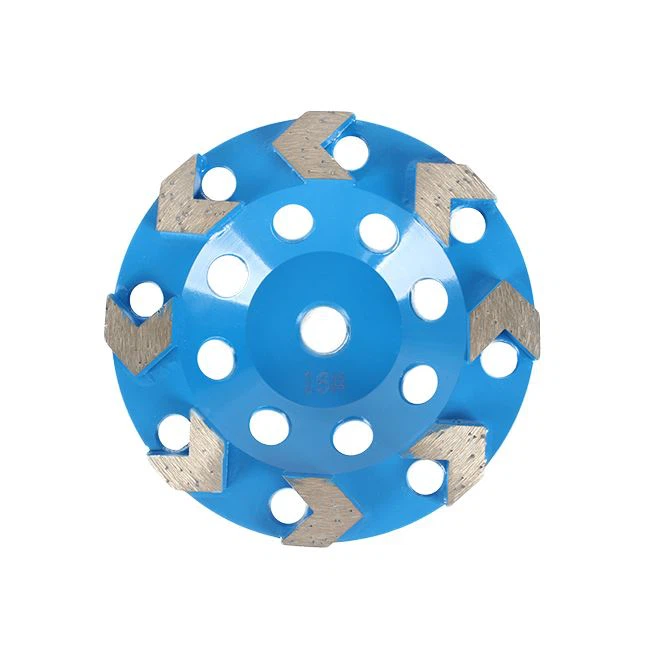

Grinding Cup Wheels: These are diamond grinding wheels that are typically used for aggressive grinding and leveling on concrete surfaces. They come in different sizes and shapes, including single and double-row segments, turbo segments, and diamond cups with segmented rims.

Polishing Pads: These are diamond polishing pads that are used for polishing concrete floors to a high gloss finish. They come in different grits and can be used on both wet and dry surfaces.

Grinding Plates: These are metal plates with diamond segments that are used for grinding and removing coatings, adhesives, and other materials from concrete surfaces.

Scarifying Cutters: These are tungsten carbide cutters that are used for scarifying and preparing concrete surfaces by removing coatings, adhesives, and other materials. They come in different sizes and shapes and can be used on both manual and machine-operated tools.

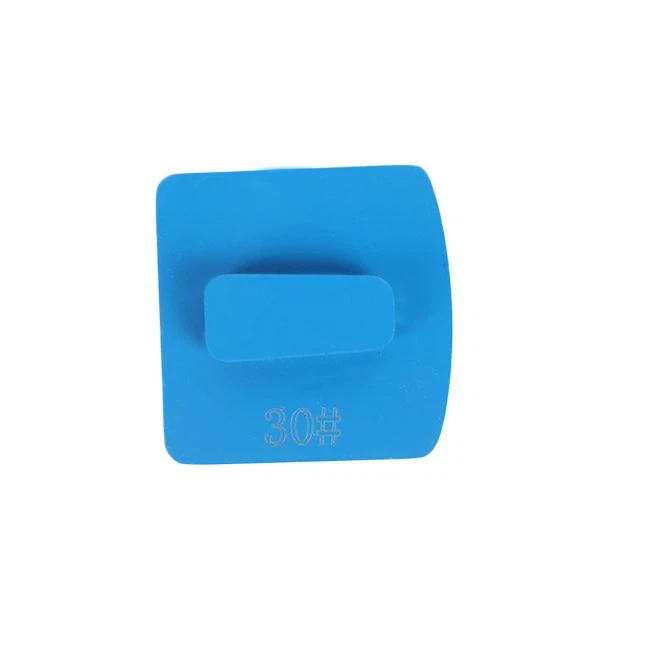

Grinding Plugs: These are metal or resin bond plugs that are used for grinding and smoothing out concrete surfaces. They come in various sizes and shapes and are ideal for small areas and tight corners.

PCD Grinding Discs: These are polycrystalline diamond (PCD) discs that are used for removing thick coatings and adhesives from concrete surfaces. They are typically used in conjunction with diamond grinding segments and come in different shapes and sizes.

Materials of Concrete Grinding Tooling

Concrete Grinding Tooling can be made of various materials depending on the specific application and desired finish. Some common materials used in Concrete Grinding Tooling include:

Diamond: Diamond is the most commonly used material in Concrete Grinding Tooling due to its hardness and abrasion resistance. Diamond tooling is used to grind and polish concrete surfaces to a high gloss finish.

Metal Bond: Metal bond tooling is made of a mixture of metal powder and diamond particles, which are fused together to create a durable grinding tool. Metal bond tooling is used for grinding and shaping concrete surfaces, and can be used wet or dry.

Resin Bond: Resin bond tooling is made of a mixture of resin and diamond particles, which are bonded together to create a flexible grinding tool. Resin bond tooling is used for grinding and polishing concrete surfaces, and is typically used in the final stages of a polishing process.

Hybrid Bond: Hybrid bond tooling is a combination of metal and resin bond tooling, which offers the benefits of both materials. Hybrid bond tooling is versatile and can be used for grinding and polishing concrete surfaces, as well as other materials such as marble, granite, and terrazzo.

Ceramic: Ceramic tooling is made of an abrasive material that is bonded to a backing material. Ceramic tooling is typically used for grinding and shaping concrete surfaces, and can be used wet or dry.

Characteristics of Concrete Grinding Tooling

Diamond Abrasives: Concrete Grinding Tooling typically contains diamond abrasives which are highly durable and strong. They can efficiently grind and smooth out the surface of concrete.

Segmented Grinding Heads: These grinding tooling types have segmented grinding heads that are capable of providing efficient and even grinding across the surface of the concrete.

Bonded Abrasives: The bonded abrasives on Concrete Grinding Tooling are suitable for rough grinding and finishing jobs. They are designed to be tough and durable, which makes them a perfect solution for large surfaces.

Coatings: Some Concrete Grinding Tooling is layered with coatings such as resin, ceramic, and metal. These coatings help to reduce friction and increase the lifespan of the tooling.

Shapes and Sizes: Concrete Grinding Tooling comes in various shapes and sizes, including discs, cups, and wheels. The size and shape of the tooling can determine the type of grinding job it can perform.

Diamond Content: Diamond content is an important factor to consider when choosing Concrete Grinding Tooling. The higher the diamond content, the more abrasive and effective the diamond tooling will be.

Compatibility: Finally, it is essential to choose tooling that is compatible with the concrete grinding machine being used. Make sure to check the manufacturer's recommendations.

Application Fields of Concrete Grinding Tooling

Concrete Grinding Tooling is essential during surface preparation, construction, and restoration industries. These toolings can be used for various applications, including:

Concrete Floor Preparation: Before installing any flooring system, concrete surfaces need to be properly prepared. Diamond grinding tooling can remove coatings, adhesives, and other contaminants, creating a clean and smooth surface for new flooring.

Concrete Polishing: Concrete polishing is a process that involves using progressively finer diamond abrasives to create a glossy surface. Grinding tooling with diamond abrasives can be used to remove surface scratches and to polish surfaces to a high shine.

Concrete Repair and Restoration: Damaged or uneven concrete surfaces can be restored and repaired using grinding tooling. These tools can be used to remove surface cracks, spalling, and other surface defects, creating a smooth and level surface.

Decorative Concrete: Grinding tooling can be used to create a range of decorative concrete finishes, including exposed aggregate, sandblasting, and more. These finishes can be used in various applications such as driveways, patios, and wall claddings.

Terrazzo Restoration: Terrazzo floors can be restored using grinding tooling to remove scratches, stains, and imperfections and to restore the original finish. The diamond tooling is specially designed for terrazzo floors and can produce a high shine finish.

Epoxy Coatings: Epoxy coatings are used to protect concrete surfaces from chemicals, wear and tear, and other damages. Grinding tooling can be used to prepare the surface for epoxy coatings and ensure proper adhesion.

Surface Preparation for Coatings: Grinding tooling is essential before applying any coating systems. Proper surface preparation including grinding, shot blasting, and scarifying is crucial in achieving a proper coating adhesion.

Concrete Grinding Tooling Hardness

The hardness of Concrete Grinding Tooling depends on the type of material being ground, the surface area being ground, and the level of abrasion resistance needed. Generally, there are three main types of hardness classifications for grinding tooling:

Soft Bond

Designed for grinding hard or fast-wearing concrete surfaces, such as concrete floors, concrete walls, and concrete countertops. These tooling have a low abrasive resistance that allows them to grind quickly and easily, but are not very durable in the long run.

Medium Bond

Designed for general-purpose grinding, such as grinding concrete driveways, sidewalks, and patios. These tooling have medium abrasive resistance, which provides good balance between speed and durability.

Hard Bond

Designed for grinding soft concrete surfaces, such as concrete walls and concrete slabs. These tooling have high abrasive resistance, which provides excellent durability and longer tool life.

The choice of the hardness of Concrete Grinding Tooling depends on the specific application and the desired outcome. It is important to select the correct tooling to ensure fast and efficient grinding with minimal damage to the concrete surface.

precautions for product use

Choose the right diamond tooling: Selecting the right diamond tooling is crucial. Choose the right tooling based on the type of concrete surface you want to grind, the hardness of the concrete and the required finish.

Prepare the surface: Clean and prepare the surface to be ground. Remove any debris, dirt, or adhesive residue. Use a floor scraper or a concrete grinder if necessary.

Install the diamond tooling: Attach the diamond tools to the grinding machine. The type of tooling will depend on the application, the size of the machine, and the desired finish. Follow the manufacturer’s instructions for installation.

Start grinding: Turn on the grinding machine and begin grinding. Move the grinder in back and forth, sweeping motions. Always keep the grinding disk parallel to the surface being ground.

Apply pressure: Apply the right amount of pressure to the machine, depending on the type of concrete being ground and the type of diamond tooling being used.

Change the diamond tooling: Change the diamond tooling periodically if necessary. Frequent changes of these tools will ensure the quality of the grinding.

Finish: Once the grinding is complete, clean up the dust and debris. Vacuum the area to remove any remaining dust or debris.

Polish: If desired, polish the concrete surface for a smooth finish. Use a polishing machine and follow the manufacturer’s instructions.

What are the Components of a Concrete Grinding Tooling

Diamond segments: The most important component of a Concrete Grinding Tooling is the diamond segments. These are the abrasive parts that grind away at the concrete surface to create a smooth and even finish. Diamond segments are made from high-quality diamonds that are glued onto a metal base.

Bond: Bond is the material that holds the diamond segments onto the metal base. It can be made of resin, metal, or a combination of both. The bond determines how hard or soft the grinding tool will be, and also affects the lifespan of the diamond segments.

Grit: The grit size of diamond segments determines the coarseness of the Concrete Grinding Tooling. Grit sizes range from coarse to fine, with finer grit sizes producing a smoother finish.

Shape: The shape of the diamond segments can vary depending on the type of Concrete Grinding Tooling being used. Some shapes are designed for aggressive grinding, while others are better suited for polishing.

Size: Concrete Grinding Tooling comes in a variety of sizes, from small handheld grinding discs to large planetary machines. The size of the tooling will depend on the size of the area being ground and the type of job being done.

What Are the Specifications of Concrete Grinding Tooling

Concrete Grinding Tooling specifications typically include the following:

Diamond segment

The diamond segment is the cutting part of the grinding tooling. It has a metal base that is bonded with diamonds. These diamonds are available in different grit sizes, and the segment's size and shape can vary depending on the tooling's intended use.

Number of segments

The number of segments on a grinding tooling can vary from one to multiple. More segments mean more grinding heads, which can increase productivity. However, a tooling with more segments may require more power to operate and may be more expensive.

Bond

The bond refers to the material used to hold the diamond segment in place. It can be metal bond, resin bond, or hybrid bond. The bond affects the tool's performance and durability.

Size and shape

The size and shape of the grinding tooling depend on the type of machine it is intended to be used with. The most common sizes are 3-inch, 4-inch, and 5-inch. The shapes can vary from round to square.

Application

Depending on the intended use, grinding tooling can be classified as coarse, medium, or fine. Coarse tooling is used for heavy grinding, while fine tooling is used for polishing or finishing.

Durability

Durability is an essential consideration in grinding tooling specifications. A durable tooling lasts longer and performs better. The tooling's lifetime can depend on the quality of materials used, the manufacturing process, and the design.

Manufacturing Requirements for Concrete Grinding Tooling

Concrete Grinding Tooling is a critical part of the manufacturing process in the construction industry. It is used to smooth, level, polish, and remove coatings from concrete surfaces. The following are essential manufacturing requirements for Concrete Grinding Tooling:

Raw materials

The raw materials used in manufacturing Concrete Grinding Tooling should be of a high quality and meet industry standards. Bond agents, diamonds, and metal powders are commonly used in the production of grinding tooling.

Precision manufacturing

The manufacturing process should be carried out with precision to create a consistent product that performs accurately. Quality control measures should be in place to detect and correct any inconsistencies.

Durability

Concrete Grinding Tooling must be durable and able to withstand the harsh conditions of the construction environment. It must also be able to maintain its sharpness over extended periods of use.

Safety

The manufacturing process must take occupational safety and health requirements seriously. The finished products must not pose any risk to the health and safety of users.

Design

The design of the tooling should be tailored to specific applications, including the type of concrete surface, grinding pressure, speed, and the expected finish quality.

Environmental impact

The manufacturing process should minimize the negative environmental impact by using environmentally friendly materials, disposing of waste responsibly, and complying with local regulations.

Parameters of Concrete Grinding Tooling

Concrete Grinding Tooling parameters include:

Abrasive type: Diamond is the most common type of abrasive used in concrete grinding tools.

Grit size: The grit size refers to the coarseness of the abrasive particles. Smaller grit sizes are used for finer finishes, while larger grit sizes are used for rougher finishes.

Bond type: The bond type refers to the material that holds the abrasive particles together. It can affect the durability, aggressiveness, and speed of the tool.

Segment shape: The shape of the segments on the tool affects the amount of material removed and the surface finish achieved. Some common shapes include round, rectangular, and trapezoid.

Segment size: The size of the segments also affects the amount of material removed and the surface finish achieved.

Segment density: The density of the segments refers to the number of segments on the tool. Higher density segments remove material more aggressively.

Tool hardness: The hardness of the tool affects the rate of wear and the aggressiveness of the tool.

Tool size: The size of the tool affects the area covered and the aggressiveness of the tool.

●Check the tools regularly for wear and damage, and replace them when necessary to ensure they are working at their best.

●Clean the tools after each use to remove any debris and prevent build-up. Use a wire brush to remove any hardened concrete or other debris.

●Store the tools in a dry place to prevent rust and corrosion. Keep them away from moisture and humidity.

●Use the correct type of grinding tool for the job. Different types of tools are designed for different surfaces and applications.

●Use the correct amount of pressure when grinding. Too much pressure can damage the tool and the surface being worked on.

●Use the correct speed and rotation when grinding. Each grinding tool has a maximum speed and rotation that should not be exceeded.

●Use the correct technique when grinding. Avoid grinding in the same spot for too long, and keep the tool moving to prevent grooves and uneven surfaces.

●Check the power source regularly to ensure it is functioning correctly. A faulty power source can damage the tool and be dangerous.

Concrete Grinding Tooling Production Process

Dressing: Once the tooling is sintered, it is dressed to give it the required finish and sharpness. Dressing is done by cutting the surface of the tooling with a diamond grit to expose the diamonds.

Quality control: The final step in the production process is quality control. The tooling is checked to ensure it meets the required specifications. The quality control process involves checking the tooling for dimensional accuracy, hardness, and abrasion resistance.

Packaging: After passing the quality control tests, the tooling is packaged for shipping to the customer. The packaging is done to prevent damage during transportation. The tooling is usually shipped in boxes or crates depending on the quantity and size.

Material selection

The first step in the production process is selecting the materials to use for the tooling. The main materials used are diamonds and metal bonds.

Diamond selection

After selecting the diamond and metal bonding materials, the supplier selects the right shape and size of diamond grit to use. They also select the right concentration of diamond grit depending on the application.

Molding

The diamond grit and metal bond are mixed together and molded into the required shape. The shape could be a cup wheel, floor pad, or segment.

Sintering

After molding, the tooling is placed in a high-temperature oven to sinter. Sintering is the process of fusing the diamond and metal together under high pressure and temperature.

Factors to Consider When Selecting Concrete Grinding Tooling

Concrete hardness: The hardness of the concrete surface you are grinding will determine the type of tooling you need. Soft concrete requires a harder bond diamond tooling, while hard concrete needs a softer bond.

Tooling size and shape: The size and shape of the tooling should match the size and shape of the grinder you are using. Larger grinders require larger tooling, while smaller grinders require smaller tooling.

Diamond grit: The diamond grit size determines the roughness of the concrete surface after grinding. Larger grits (lower numbers) are more aggressive and remove more material, while smaller grits (higher numbers) are less aggressive and polish the surface.

Segments: The segment design of the tooling affects the performance of the grinder. Double segment tooling is more aggressive and removes material quickly, while single segment tooling is better for finer finishes.

Quality: The quality of the tooling affects its durability and performance. High-quality tooling lasts longer and performs better than lower-quality options.

Application: Consider the application of the concrete surface after grinding. If you plan to apply a coating or polish, you will need a finer grit tooling. If you are removing a coating or roughening the surface for better adhesion, you will need a more aggressive tooling.

Budget: Finally, consider your budget when selecting tooling. Although higher-quality tooling is more expensive, it may be more cost-effective in the long run due to its durability and performance.

Our Factory

Founded in 1994, TRUE SHINE is one of the world's leading manufacturers of stone and concrete grinding and polishing materials.As a technology-driven company, research and development has always been a core element of TRUE SHINE. With years of experience and a strong spirit of innovation, the company has built many excellent products and become one of the world's leading abrasives manufacturers.

Our Certificate

FAQ

We're professional Concrete Grinding Tooling manufacturers and suppliers in China since 1994, specialized in providing the best customized service with competitive price. Welcome to wholesale bulk high quality Concrete Grinding Tooling made in China here from our factory.

Stone Polishing Pads, Diamond Grinding Segments For Husqvarna, Snail Lock Back Holder