Stone Polishing Pads

Why Choose Us

High-quality products

The company is committed to producing high-quality products that meet customer's standards. The company uses advanced technology and equipment to ensure consistency in the quality of its products.

Diverse range of products

The company offers a wide range of grinding tools such as diamond tools, resin tools, ceramic tools, and metal bond tools, among others, to meet the needs of its customers.

Competitive pricing

The companyprovides customers with competitive pricing on its products without compromising their quality.

Excellent customer service

The company has a team of dedicated customer service staff who are always ready to assist customers with their needs and concerns.

What is Stone Polishing Pads

Stone Polishing Pads are specially-designed tools that are used to remove surface stains and scratches from natural and engineered stones. They are commonly used in the construction industry for polishing and finishing surfaces such as marble, granite, and concrete. Stone Polishing Pads are available in different sizes and diameters, and the grit size determines the level of abrasiveness. They are often used with a handheld or floor polisher and can be wet or dry. Overall, Stone Polishing Pads are an essential tool in achieving a smooth, shiny, and scratch-free surface on stone materials.

Advantages of Stone Polishing Pads

Greater Efficiency: Stone Polishing Pads are designed to enhance the efficiency and speed of the polishing process. They are designed for specific applications, which makes them more effective than other polishing tools.

Versatility: Stone Polishing Pads can be used on a range of surfaces, including marble, granite, concrete, and terrazzo. This makes them a versatile tool for professional cleaners and builders.

High-Quality Finish: Stone Polishing Pads deliver a superior level of shine and finish to stone surfaces. They remove even the finest scratches and marks from the surface.

Cost-Effective: Using Stone Polishing Pads is a cost-effective approach to maintaining and polishing stone surfaces. They are reusable and provide long-lasting service.

Ease of Use: Stone Polishing Pads are easy to use and require minimal training. They can be used with a variety of polishing machines and accessories.

Safe to Use: Stone Polishing Pads are a safe and reliable way to polish stone surfaces. They are designed to prevent damage and scratches to the surface and maintain its integrity.

Consistency: Stone Polishing Pads provide consistent results, leaving a precise finish that is hard to achieve with other polishing tools.

Multiple Grits Available: There are different grits available for Stone Polishing Pads, from coarse to fine. This ensures that you can achieve the desired level of shine and finish on the surface.

What Are Stone Polishing Pads Used For

Stone Polishing Pads are used for polishing and buffing various types of stone, including granite, marble, and other natural stones. They are typically used in the stone fabrication and restoration industry to produce a high-gloss or honed finish on the surface of the stone. This process involves using a series of pads with varying levels of grit, starting with a coarse grit to remove any rough areas or scratches and gradually progressing to finer grits to achieve the desired level of shine. Stone Polishing Pads can also be used for cleaning and maintaining stone surfaces by removing stains, dirt, and grime.

Types of Stone Polishing Pads

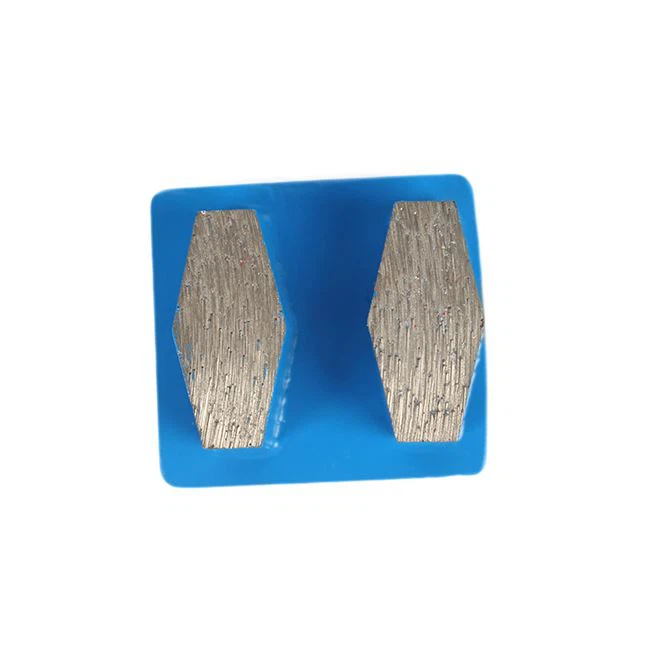

Electroplated Polishing Pads: These pads have diamond abrasive particles that are electroplated onto the surface of the pad. They are extremely aggressive and are used for removing deep scratches and chipping on hard surfaces like concrete.

Buffing Pads: These are made of wool or synthetic materials and are used for the final buffing or shining of surfaces. They are ideal for use on granite, marble, and other natural stones.

Honing Pads: These pads are used for the initial stages of polishing to remove any scratches and imperfections. They come in various grit levels and are designed to prepare the surface for final polishing.

Diamond Polishing Pads

These are the most commonly used polishing pads for stone and concrete surfaces. They come in various grit levels for different levels of polishing.

Resin Polishing Pads

These are made of a mixture of resin and diamond abrasive particles. They offer excellent durability and are ideal for polishing marble, granite, and other soft stones.

Burnishing Pads

These are used for high-speed buffing to give the surface an extra shine. They are designed for use on marble, granite, and other natural stones.

Specialty Pads

There are several specialty pads available that are designed for specific applications, such as removing dark stains from marble or polishing edges and corners.

Stone Polishing Pads can be made of various materials such as diamond, resin, ceramic, and metal.

Diamond pads are the most commonly used type of pads for polishing natural stones such as granite, marble, and sandstone. These pads are made of tiny diamond particles that are embedded in a flexible resin matrix. The diamond particles provide a high level of abrasion and allow for a smooth finish.

Resin pads use synthetic resins to create a warm, glossy finish. They are also commonly used for polishing concrete floors and terrazzo.

Ceramic pads are made of abrasive particles that are held in a ceramic matrix. They offer a more aggressive cutting action than resin pads, making them suitable for removing scratches or heavy wear on floors.

Metal pads are made of metal particles embedded in a matrix, and they are used for heavy-duty polishing. They are typically used to remove scratches or high spots on concrete floors.

Characteristics of Stone Polishing Pads

Material: Stone Polishing Pads are made of diamond abrasives or resin abrasive material.

Grit: The grit level starts from 50 and can go up to 3000. The lower the number, the coarser the pad, and the higher the number, the finer the pad.

Size: Stone Polishing Pads are available in various sizes ranging from 3 inches to 8 inches.

Durability: The durability of Stone Polishing Pads depends on the quality of the material. Diamond abrasives are more durable than resin abrasives.

Water absorption: The water absorption rate of the pad is an important factor as it helps in keeping the surface cool during the polishing process. Resin pads have a lower water absorption rate than diamond pads.

Flexibility: Stone Polishing Pads should be flexible to conform to the surface of the stone for effective polishing.

Grip: Polishing pads need to have a good grip to the polishing machine to ensure a smooth and even polishing action.

Versatility: These pads are not only limited to polishing stone surfaces but can also be used on concrete and terrazzo surfaces.

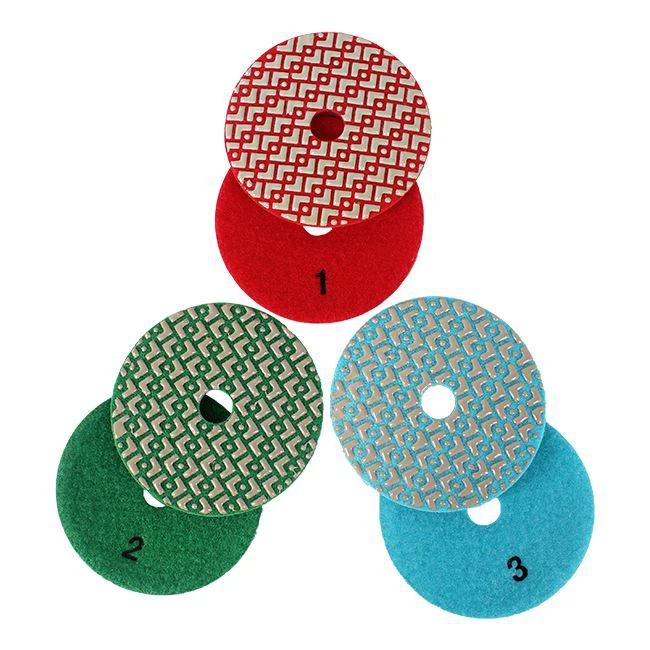

Color coding: Stone Polishing Pads come in different colors to indicate the level of grit. This helps to easily choose the right pad for the desired level of polish.

Maintenance: Stone Polishing Pads need to be cleaned after each usage to maintain their effectiveness. Resin pads can be cleaned with water, while diamond pads need special cleaning solutions.

Application Fields of Stone Polishing Pads

Construction industry: Stone Polishing Pads are commonly used in the construction industry for various purposes, such as polishing floors, walls, countertops, and stairs made of natural stones like granite, marble, and travertine.

Monument and memorial industry: Stone Polishing Pads are used to restore and polish granite and other natural stone memorials, gravestones, and statues.

Kitchen and bathroom remodeling industry: Stone Polishing Pads are used to polish and restore natural stone countertops, backsplashes, and floors in kitchens and bathrooms.

Automotive manufacturing and repair: Stone Polishing Pads are used to polish glass and metal surfaces on automobiles.

Jewelry manufacturing and repair: Stone Polishing Pads are used to polish precious stones, such as diamonds, rubies, and sapphires, for use in jewelry.

Arts and crafts industry: Stone Polishing Pads are used by artists and crafters to smooth and polish natural stones for use in jewelry, sculptures, and other artistic creations.

Boat and yacht maintenance: Stone Polishing Pads are used to maintain and restore the appearance of natural stone surfaces on boats and yachts, such as decks, countertops, and bathroom fixtures.

Restoration industry: Stone Polishing Pads are used to restore the appearance of historic buildings, monuments, and other structures made of natural stone.

Stone Polishing Pad Hardness

Stone Polishing Pads come in a range of hardness levels, typically measured on the Mohs scale of mineral hardness. The higher the number on the Mohs scale, the harder the mineral and the more abrasive the polishing pad.

Here are some common stone polishing pad hardness levels and the types of stones they are best used for:

Soft (3-4 Mohs)

Best for delicate stones like marble and limestone, which can be easily scratched. Soft pads are also used for the final polishing stage on harder stones.

Medium (5-6 Mohs)

Good for polishing most natural stones, including granite, quartzite, and sandstone. Medium pads remove minor scratches and imperfections and leave a polished finish.

Hard (7-8 Mohs)

Ideal for polishing quartz and engineered stones, which have a higher hardness level. Hard pads will also work well on harder natural stones, but may leave some visible swirls or scratches.

Extra Hard (9-10 Mohs)

Designed for the hardest stones, like diamond and some types of granite. These pads are extremely abrasive and should only be used by professionals.

How to Use Stone Polishing Pads

Stone Polishing Pads are essential tools for maintaining the shine and appearance of natural stone surfaces like granite, marble, and travertine. Here are some steps to follow when using them.

Clean the surface: The first step is to clean the surface to remove any dirt, debris, or stains. Use a pH-neutral stone cleaner and a soft cloth to avoid scratching the stone.

Attach the polishing pads: Depending on the type of pads you have, you may need to attach them to a polisher or grinder. Follow the manufacturer's instructions carefully to ensure safe and proper usage.

Choose the right pad: There are different types of polishing pads, each with a specific grit level, from coarse to fine. Start with the lowest grit level and gradually work your way up to achieve a smooth and shiny finish.

Wet the surface: Wet the surface with water or a polishing solution to help the pads glide smoothly over the surface while minimizing overheating and dust.

Begin the polishing process: Start with the lowest grit level pad and work each area in a circular motion for a few seconds, then move to the next grit level. Repeat the process until you reach the desired shine level.

Finished by wiping the surface clean with a soft cloth to remove any residue and enjoy the new shine.

Repeat the process as needed: Stone surfaces may require periodic polishing maintenance, so repeat the process as necessary to maintain the desired shine.

Foam Layer: This layer provides cushioning and helps the polishing pad contour to the surface of the stone.

Cooling System: Some advanced polishing pads have a water feed system that cools the pad and the surface of the stone during the polishing process.

Resin Bond

This is the material that binds the diamond abrasive particles to the polishing pad.

Diamond Abrasive

This is the cutting material that removes the surface layer of the stone to create a polished finish.

Velcro Backing

This is the attachment mechanism that allows you to attach the polishing pad to a backing disc.

What Are the Specifications of Stone Polishing Pads

Stone Polishing Pads vary in specifications depending on the intended use and the type of stone being polished. However, some common specifications include:

Material: Most Stone Polishing Pads are made from diamond particles embedded in a resin bond. Some pads are also made from ceramic materials or a combination of both.

Grit: The grit size of the polishing pad determines its coarseness or fineness. Lower grit numbers are coarser and are used for initial grinding, while higher grit numbers are finer and used for polishing.

Diameter: The size of the polishing pad varies from 3 inches to 7 inches or more, depending on the size of the polishing machine.

Thickness: The thickness of the polishing pad also varies, from 2mm to 5mm or more.

Hook and loop backing: Most polishing pads have a hook and loop backing that allows them to be easily attached to and removed from a polishing disc.

Water usage: Some polishing pads are designed for wet use and require water to prevent overheating and to lubricate the surface being polished.

Application: Stone Polishing Pads are used for different applications, such as polishing marble, granite, concrete, and other stone surfaces. The specifications of the pad will depend on the type of stone it is used for.

Manufacturing Requirements for Stone Polishing Pads

Abrasive Material: The polishing pad should be made from high-quality abrasive materials like diamond, silicon carbide, or resin. These materials must be durable and capable of withstanding high pressure and friction during the polishing process.

Backing Material: The backing material of the polishing pad must be strong and resilient. It should be able to hold the abrasive material firmly and maintain its shape and structure during use.

Size and Thickness: The size and thickness of the polishing pad should be suitable for the type of stone being polished. Generally, polishing pads come in sizes ranging from 4 inches to 7 inches in diameter, and thickness ranges between 2mm to 5mm.

Grit Rating: The grit rating of the polishing pad determines the level of abrasiveness. The polishing pads’ grit rating should be selected based on the level of polish required, the hardness of the stone, and the type of polish being used.

Water Flow: The polishing pad must have adequate water flow to lubricate the stone surface and keep the pad cool during the polishing process.

Compatibility: The polishing pad should be compatible with different types of polishing machines, such as hand-held grinders, floor machines, or hand polishers.

Longevity: The polishing pads must be able to withstand the polishing process, maintain their shape and structure, and last for a long time.

Efficiency: The polishing pad must be efficient in removing scratches, stains, and blemishes from the stone surface.

Flexibility: The polishing pad should be flexible enough to adapt to the curvature of the stone surface, especially in the case of round stones.

Ease of Use: The polishing pad should be easy to attach and detach from the polishing machine and should not require too much effort to operate.

Parameters of Stone Polishing Pads

Grit size

The grit size of a stone polishing pad determines the level of abrasiveness and aggressiveness of the pad. The grit sizes typically range from 50 to 3000, with lower numbers indicating coarser grits and higher numbers indicating finer grits.

Pad thickness

The thickness of a stone polishing pad can range from 2mm to 5mm. Thicker pads are typically more durable and long-lasting, while thinner pads are more flexible and better suited for curved and uneven surfaces.

Bonding material

The bonding material is what holds the abrasive particles together in the pad. The most common bonding materials for Stone Polishing Pads are resin and metal, with resin being more flexible and better suited for softer stones like marble and metal being more rigid and better suited for harder stones like granite.

Application

Stone Polishing Pads can be used for a variety of applications, including polishing and buffing natural stone surfaces, concrete, and engineered stone. The specific application will determine the type of pad needed, as well as the grit size and bonding material.

Pad shape

Stone Polishing Pads come in a variety of shapes, including round, rectangular, and triangular. The shape of the pad should be chosen based on the shape of the stone being polished.

Wet or dry use

Stone Polishing Pads can be used wet or dry, depending on the specific application. Wet polishing pads are designed to be used with water, which helps to cool the pad and prevent overheating. Dry polishing pads are designed to be used without water and are typically used for final finishing and buffing.

Stone Polishing Pads Maintenance Tips

Clean the pads after each use

After each use, you should clean the polishing pads using a pad washer or a hose. This will remove any remaining residue or debris from the previous job.

Dry the pads after cleaning

After cleaning the pads, make sure to dry them completely before using them again. You can leave them in the sun or use a towel to dry them.

Store the pads properly

When storing the pads, make sure to keep them in a dry and clean place, away from direct sunlight. You can also use plastic bags or cases to protect them from dust or moisture.

Wash the pads regularly

Regular washing of the polishing pads will help to extend their lifespan. Use a cleaning solution that is specifically designed for Stone Polishing Pads.

Avoid using harsh chemicals

Do not use harsh chemicals, such as bleach or acids, to clean the pads as they can damage the pads' surface and reduce their lifespan.

Replace the pads when needed

After several uses, the polishing pads will start to wear out. When you start to notice the pads are losing their effectiveness, it is time to replace them.

The production process of Stone Polishing Pads involves several steps:

Raw material selection: The first step is to select the appropriate raw materials required for making the polishing pads. Usually, the manufacturer selects high-quality resin, diamond, and other necessary materials, depending on the type of stone being polished.

Preparation of the mix: Once the raw materials are selected, the next step is to prepare the mix. In this step, the manufacturer mixes the resin and other materials at a specific ratio to create a uniform mixture.

Heating and curing: Once the mix is molded, it is heated and cured at a high temperature using an oven. The high temperature helps in solidifying and hardening the mix and creating a strong bond between the diamond particles and the resin.

Packaging: Once the polishing pads have been tested and approved, they are packaged for distribution and sale to the market. The packaging also includes proper labeling and instructions for use.

Factors to Consider When Selecting Stone Polishing Pads

Type of Stone: Different types of natural stones require different types of polishing pads. For example, marble, granite, and travertine each demand specific polishing pads.

Grit: The grit of the polishing pad will impact how fine or coarse the final finish of the stone will be. Lower grits are more abrasive and work well for removing blemishes and coarse finishes, while higher grits produce smoother results.

Size: Consider the size of the polishing pad, depending on the size of the stone you are working on.

Durability: Durable pads are necessary for polishing rough and uneven stones. Some polishing pads last longer than others but might not be as effective.

Wet vs. Dry: Some polishing pads require the use of water to achieve optimal results and maintain their coarseness while others can be used dry on a stone.

Quality: Look for high-quality pads that are made from top-quality materials, as they will last longer and often give better results.

Price: The cost of a polishing pad should be considered, especially if you frequently work with stones. Cheaper options might not last as long and require frequent replacement, which can end up costing more.

Our Factory

Founded in 1994, TRUE SHINE is one of the world's leading manufacturers of stone and concrete grinding and polishing materials.As a technology-driven company, research and development has always been a core element of TRUE SHINE. With years of experience and a strong spirit of innovation, the company has built many excellent products and become one of the world's leading abrasives manufacturers.

Our Certificate

FAQ

We're professional Stone Polishing Pads manufacturers and suppliers in China since 1994, specialized in providing the best customized service with competitive price. Welcome to wholesale bulk high quality Stone Polishing Pads made in China here from our factory.

Diamond Polishing Pad For Marble Floors, PCD Diamond Tooling, Segment Grinding Wheel